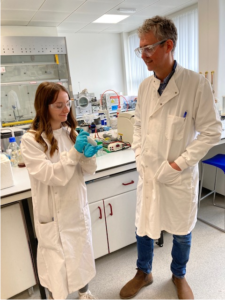

A Liverpool-based scientist is developing research that could change our relationship with plastic.

Dr Andrew Carnell, of the University of Liverpool, is pioneering the use of enzymes to make plastics more environmentally friendly.

His main area of research in developing bio renewable alternatives to PET, the most commonly used thermoplastic polymer in the world.

The biggest concern with plastics is the environmental impact they cause. Roughly 300 million tonnes of plastic waste is produced every year worldwide- much ending up in landfill or in oceans.

Dr Carnell is creating bioplastic intermediates such as FDCA which are the “building blocks” of bioplastics.

“FDCA is a bio-derived, sustainable replacement for petrochemically derived terephthalic acid” says Dr Carnell “which can be used to make alternatives to PET plastic- which is what goes into plastic bottles.”

This type of plastic would be environmentally friendly and could be compostable, whereas oil-based PET doesn’t degrade for 400 years. This would fundamentally change how plastics are disposed of and the environmental impact plastic would have on the environment.

Dr Carnell and his team have already developed a combination of four enzymes capable of converting the biologically-derived material HMF into the building block lFDCA, but it is too expensive to produce on scale.

“Now we’ve got a project, that’s ongoing, to find, ideally, a single replacement for those four enzymes,” says Dr Carnell

“We’ve developed a panel of enzymes that might provide a suitable drop-in replacement for all or at least one of the enzymes that is too expensive to produce on scale.”

From that panel they’ve already found hits that are encouraging. They are narrowing this down by changing the genes in these enzymes by creating hundreds of thousands of variants and then identifying and sorting the most promising strains.

Dr Carnell is not just looking to change the way new plastics are created but how they can be reused: “Something we’ve been looking at alongside that is looking at enzymes for degrading plastics.

“It’s still early days. In terms of operationally how you would do it, I think you’d have to have a recycling point where you’d have large vessels containing the enzyme and water and perhaps some solvent into which you’d put your shredded PET plastic.

“Then you wait some time and you’d get a solution with the monomers of the degraded polymer or ideally the monomer could be made to separate from the water layer.”

This type of technology is already being developed in France with the Toulouse Biotechnology Institute having already set up a test process that degraded 90% of the PET plastics in 10 hours.

According to Dr Carnell the possibilities of what can be done with the broken-down products are surprising: “There’s one really nice example in literature recently reported by a group at Edinburgh University .

“It was demonstrated that you can degrade polyethylene terephthalate (PET) using an enzyme.

“Then you can take the monomer you produce – the terephthalic acid which is the breakdown product and then use a microbial strain which has been engineered to convert that terephthalic acid into vanillin which is the flavouring compound.”

Dr Carnell’s team have also got their own research into what can be created using these materials.

“We’ve got some research that’s ongoing to do something similar” says Carnell “where we break down the PET to terephthalic acid and we use several enzymes to try and make that terephthalic acid into a pharmaceutical drug.”

According to Dr Carnell: “The ultimate aim is to have what’s called a circular economy for plastic,” but he says that currently that is a little way off.

“At the moment one of the issues is that petro-chemically derived plastics are still much cheaper and they are well established. It’s going to take time for, new types of bioplastics to replace them and to become economically viable.”

World first as LJMU scientists lead in conservation technology